PRODUCT ADVANTAGES

METAL DEBURRING MACHINE

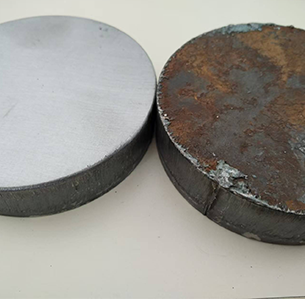

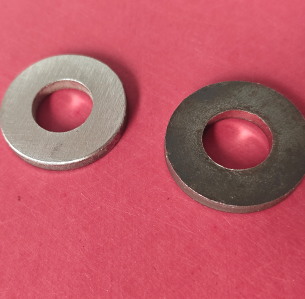

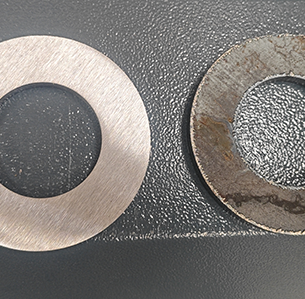

This equipment has both strong processing capacity and high flexibility. It can efficiently remove tough slag, burrs and oxide scale on the workpiece surface, and can complete precision processing such as hairline brushing and edge rounding.

The equipment supports flexible switching between wide sanding belt or universal roller brush operation modes according to process requirements, and can also be replaced with 3M polishing rollers to achieve fine processing of various metals, wood and plastics.

Suitable for multiple processes such as deburring, sanding, brushing, grinding, texturing, matte finishing and soft polishing, especially good at sand texture polishing and mirror finishing of stainless steel.

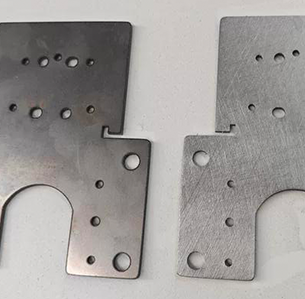

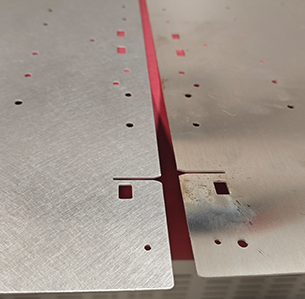

Suitable for slag and burrs generated by thermal processing such as laser, flame and plasma, as well as burrs and sharp edges generated by cold processing such as stamping and shearing.Processing thickness: 0.8-100mm; minimum processing workpiece size: ≥100×100mm; maximum width: 1000mm.