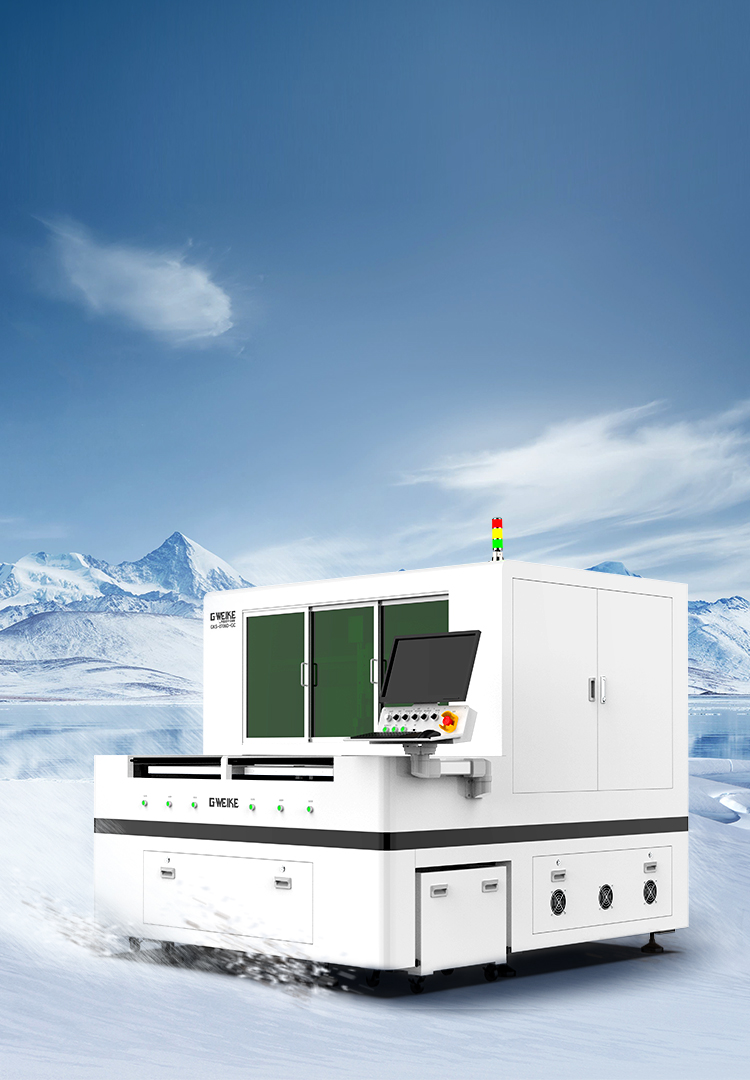

GKS-0706D-GC

DUAL-PLATFORM GLASS CUTTING & SCRIBING

INTEGRATED MACHINE

DUAL-PLATFORM GLASS CUTTING & SCRIBING INTEGRATED MACHINE

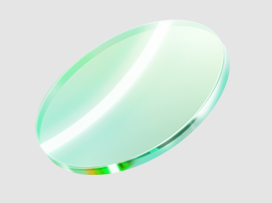

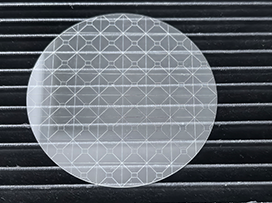

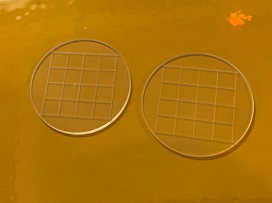

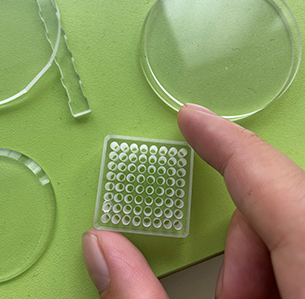

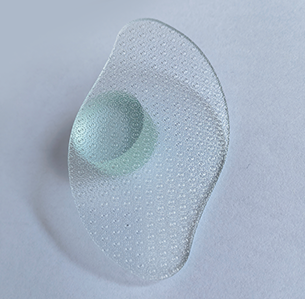

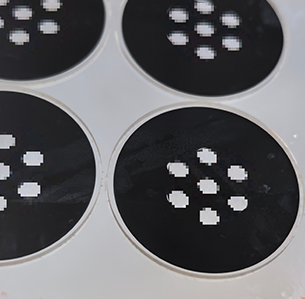

Both cutting and scribing

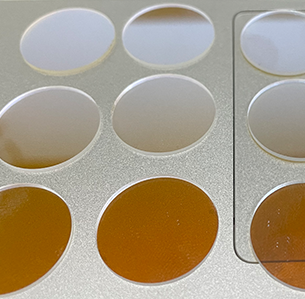

With minimal slicing damage

Small chipping on scribed edges

PRODUCT ADVANTAGES

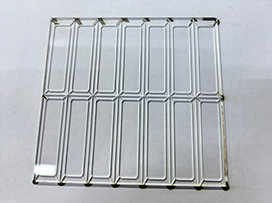

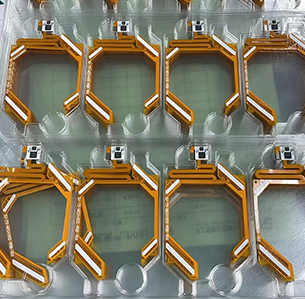

THE DUAL-PLAFORM GLASS CUTTING & SCRIBING INTEGRATED MACHINE

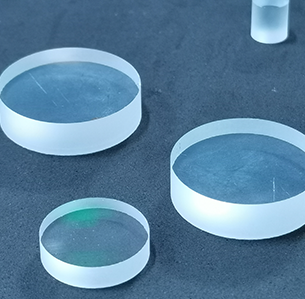

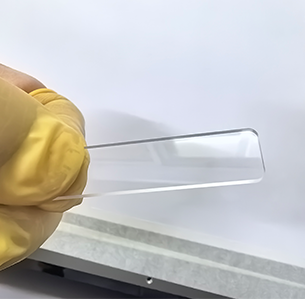

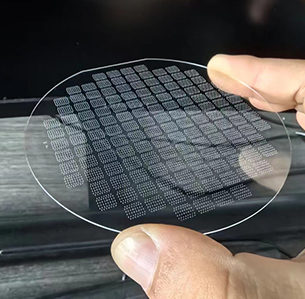

The Dual-Platform Glass Cutting & Scribing Integrated Machine integrates high-precision cutting and clean scribing processes into a single device.The maximum linear speed can reach 500mm/s, and the curve speed can also reach 300mm/s.The processing process hardly generates microcracks, breakage or chipping. The finished product has good edge integrity, and its fracture resistance is significantly better than that of the traditional step-by-step processing method.

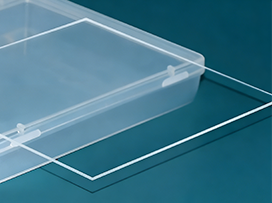

Adopting infrared picosecond laser processing, it has minimal heat impact, no deformation and no indentation, and does not require secondary processing such as grinding and polishing.

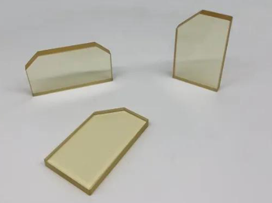

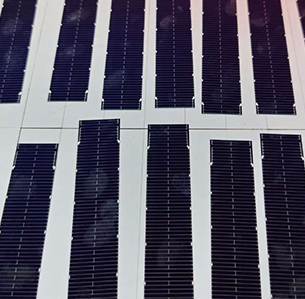

It is suitable for cutting glass covers of mobile phones, cameras, smart watches, sapphire covers, in-vehicle glass covers, interior and exterior rearview mirrors, smart home display covers, etc.Processing thickness ≤10mm, comprehensive processing accuracy ±0.02mm, and it can achieve one-time cutting of 12mm thick high-transparency glass